boxes!

boxes! CPP 64-67 Nova Stock Spindle Front Disc Brake Conversion kit install

This page describes the installation of Classic Performance Products' 64-67 stock spindle front disc brake conversion kit. Aside from the obvious improvement of a disc setup over the stock drum brakes, this kit has two major benefits. First the kit is designed to work with the stock 5-lug (64-67) front spindles. No need to modify the bracket mounting boss as with the 68-74 retrofit approach. Second, this kit is designed to keep the track width the same as it was originally. Again, the 68-74 retrofit approach falls short, as that will push the front wheels out about 1/2" per side. That can cause your tires to rub if you are tight for space.

[WARNING/DISCLAIMER: use this information at your own risk, modifying automobile brake systems can lead to dangerous situations, always have a trained mechanic check your work, I take no responsibility for the results, you've been warned, you're on your own...]

10/6 - Just getting started with this install...boxes arrived earlier today, haven't had time to do much more than open the boxes and see what's inside. MUCH more info to come later, but thought folks would like to see the new shiny bits ASAP. Some quick photos of what arrived (pretty raw, haven't sorted through these yet, some are dups to avoid flash glare...)

boxes!

boxes!

This is what's in the kit

This is what's in the kit

rotor/hub - one piece

rotor/hub - one piece

back of rotor/hub

back of rotor/hub

brake pad ASA-350-FF 7070A

6110

brake pad ASA-350-FF 7070A

6110

new hoses!

new hoses!

caliper brackets

caliper brackets

hardware kit...spindle nuts,

bearings, bracket bolts, dust cover

hardware kit...spindle nuts,

bearings, bracket bolts, dust cover

This is not part of the kit,

but I got the new CPP master cylinder with built-in proportioning valve

This is not part of the kit,

but I got the new CPP master cylinder with built-in proportioning valve

It's tough to take good pictures

of shiny stuff! Very nicely polished...

It's tough to take good pictures

of shiny stuff! Very nicely polished...

Brake line set (also not

part of kit) that I'll use as a starting point. This will need to be modified

to fit the new master cylinder.

Brake line set (also not

part of kit) that I'll use as a starting point. This will need to be modified

to fit the new master cylinder.

Removing drum brakes from spindle:

Getting started...

Getting started...

Original drum setup

Original drum setup

Original MC with Hurst Line-Lock

Original MC with Hurst Line-Lock

Tire off, ready to work

Tire off, ready to work

Pull the drum off the hub

Pull the drum off the hub

Drum off hub

Drum off hub

11.25" outside diameter

drum

11.25" outside diameter

drum

First step is to remove top

springs

First step is to remove top

springs

Be careful prying! Springs

will pop off with great force

Be careful prying! Springs

will pop off with great force

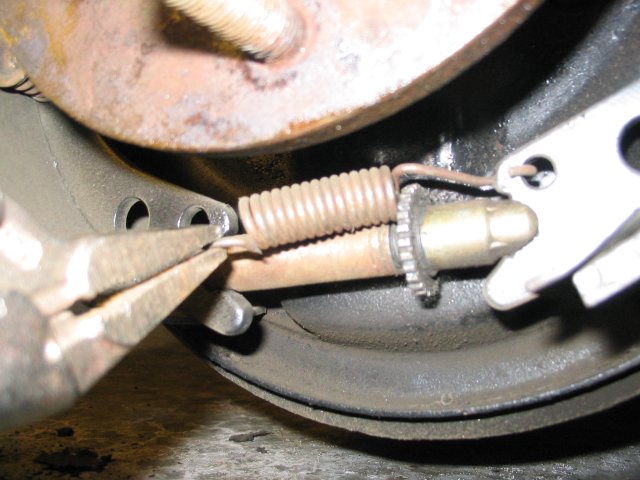

Vice-Grips work well to remove

springs too

Vice-Grips work well to remove

springs too

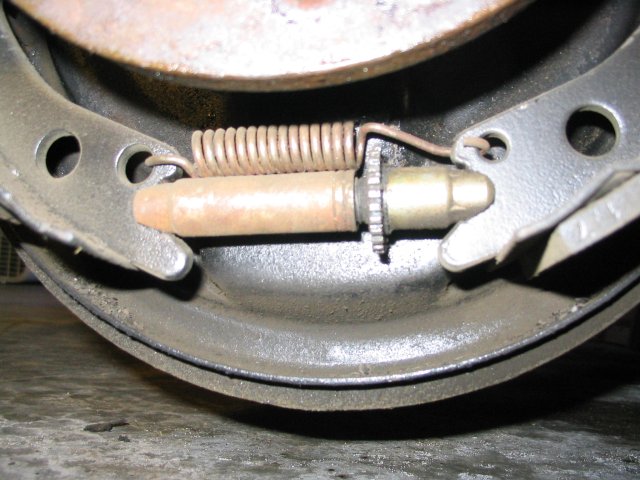

Drum adjuster and spring

Drum adjuster and spring

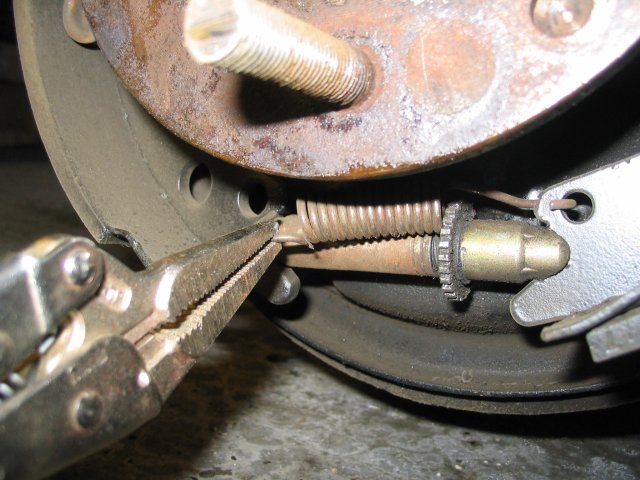

Remove adjuster spring

Remove adjuster spring

Remove adjuster

Remove adjuster

Shoes are attached with spring

clips

Shoes are attached with spring

clips

Push in, turn 90*, and release

slowly.

Push in, turn 90*, and release

slowly.

Shoes, springs, and adjuster

removed

Shoes, springs, and adjuster

removed

Pry off dust cap on hub

Pry off dust cap on hub

Spindle nut and cotter pin

Spindle nut and cotter pin

Remove cotter pin

Remove cotter pin

Remove spindle nut

Remove spindle nut

Remove washer

Remove washer

...and outer bearing.

...and outer bearing.

Pull hub off spindle

Pull hub off spindle

Remove lower bolts on backing

plate.

Remove lower bolts on backing

plate.

Top bolt has square washer

with retaining tabs bent

Top bolt has square washer

with retaining tabs bent

After tabs are flattened,

remove top nut

After tabs are flattened,

remove top nut

Remove backing plate from

spindle

Remove backing plate from

spindle

Remove hose from wheel cylinder

Remove hose from wheel cylinder

...and drain fluid into a

container

...and drain fluid into a

container

Remove top of MC to speed

draining

Remove top of MC to speed

draining

Some fluid already drained

Some fluid already drained

nearly empty...

nearly empty...

Repeat for other side

Repeat for other side

patman@bracketracer.com

Unless otherwise specified, all text and images on this page are © Copyright 2006 by Pat Mancuso.