From some searching on the internet, the transmission appears to be an NV3500. This has a hydraulic clutch. The master cylinder is mounted on the firewall, the slave is integral to the throwout bearing inside the transmission. This is the setup for an early model of the transmission. Later models had an external slave cylinder that used a lever to move the throwout bearing as a traditional mechanical linkage would. The benefit of the later model is that the slave can be accessed and replaced without removing the transmission, and the master+line+slave can be bench-bled before installation. This earlier style requires removing the transmission in order to get to the throwout bearing.

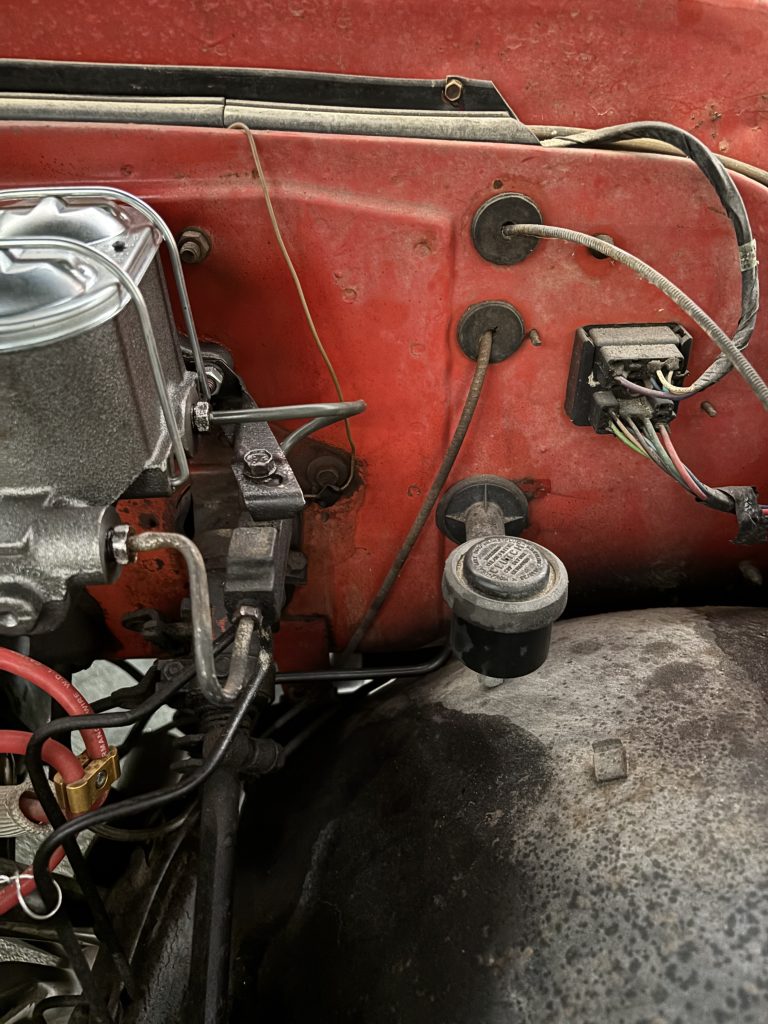

There is supposed to be a ‘quick disconnect’ that allows the line to be removed from the fitting on the throwout bearing. The picture above shows a plastic piece that I haven’t found described anywhere. It seems like it should be able to be removed to access the disconnect, but I haven’t figured that out yet.

The previous owner moved the master cylinder from the donor vehicle (1998? GMC pickup?) along with the engine and transmission. They connected the existing clutch pedal to the hydraulic master using a long bolt through a hole drilled in the plastic plunger of the master. Aside from the problem of the carriage bolt eventually breaking the plastic plunger, the connection is very low on the pedal, the leverage is poor, and the clutch is very very hard to depress.

I purchased a proper retrofit from Speedway Motors that includes a plate to reinforce the firewall, a new clutch master cylinder, and some better hardware for attaching it to the original pedal. This puts the connection much closer to the pedal pivot, and provides much better mechanical advantage. The problem is that the line between the slave and the new master needs to be replaced, which means figuring out a way to disconnect it from the slave, and then bleeding the air out of it when the new line is connected.