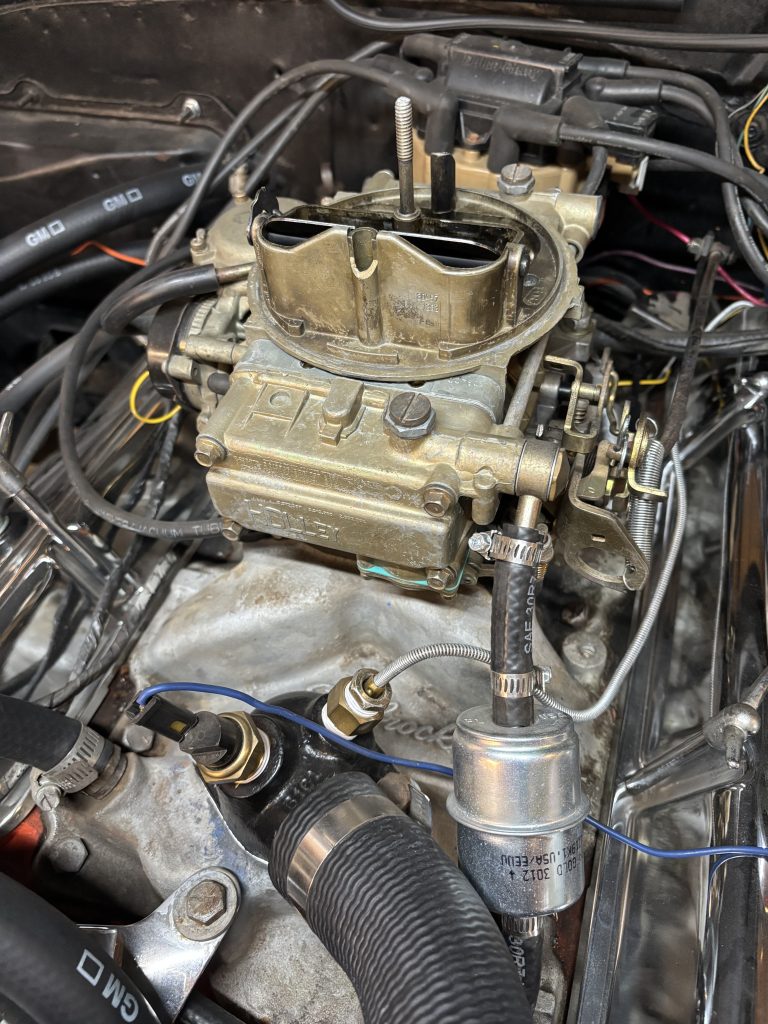

I rebuilt the carb a couple of years ago, but I hadn’t really done much with it aside from setting the idle and idle mixture. Based on what the plugs looked like, and the odor in the garage after I parked it, the mixture was rich. I decided to put in smaller jets to see if I could get that solved.

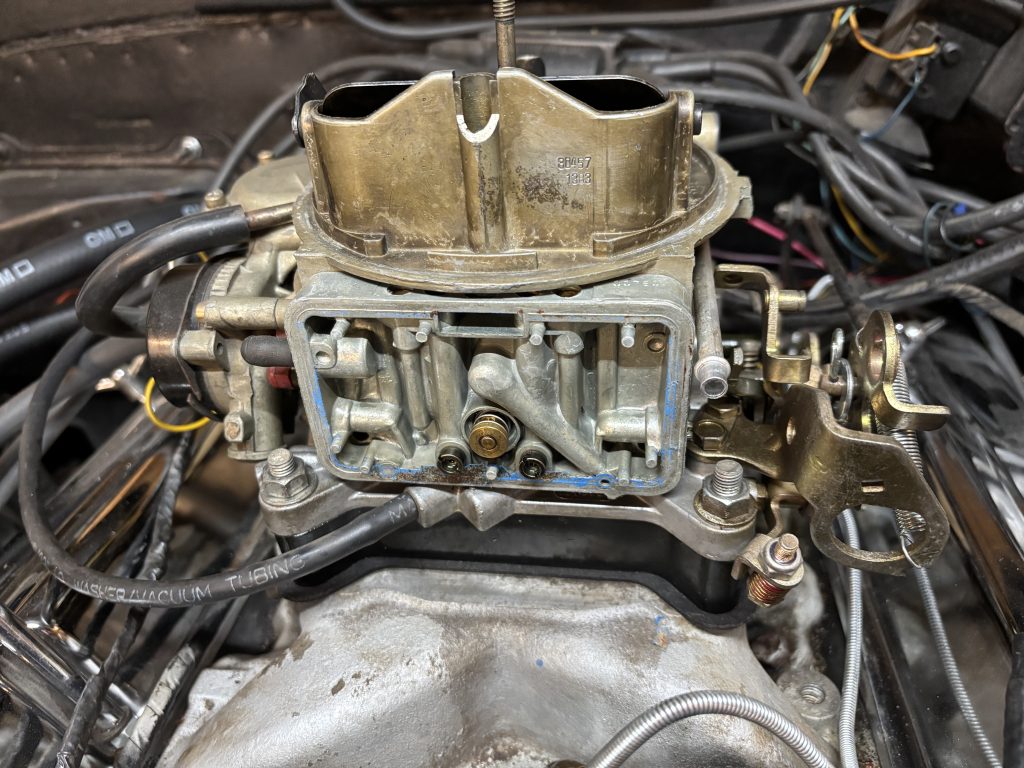

This carb has a metering block with replaceable jets in the primary side, and a metering plate with a fixed hole drilled in them. I wasn’t too concerned about the secondaries, and changing that would mean buying a new metering plate, or converting the plate to a metering block with jets.

There were #69 jets in the primary, which were the ones that were in it when I bought the car.

I decided to try #67 jets, and put in new plugs while I was at it.

The new jets were an improvement, but it still smelled rich. Also, there was a bog on acceleration, probably due to the smaller jets. I put on a bigger accelerator pump cam, and switched the jets down again to #65.

That change worked out great. The acceleration was smooth, no more bog. Also the engine was running smoother overall, and the garage didn’t smell after I parked the car.