The first order of business is getting the brakes working. It’s not a good idea to get it to move if you can’t get it to stop. PO installed an aftermarket front disk brake conversion, which looks absolutely brand new. After looking at some pictures online, I decided it’s based on the generic 1973-and-newer GM setup. The flex lines are new, and were connected to the original hard lines.

The rear brakes are the original 11″ x 2″ drum brakes. Everything retains the original 6-lug bolt pattern.

After trying the brake pedal a few times, it went all the way to the floor with minimal resistance. No brakes. Later I discovered one of the hard lines running from the rear junction block on the differential was leaking. After replacing that line, still no brakes.

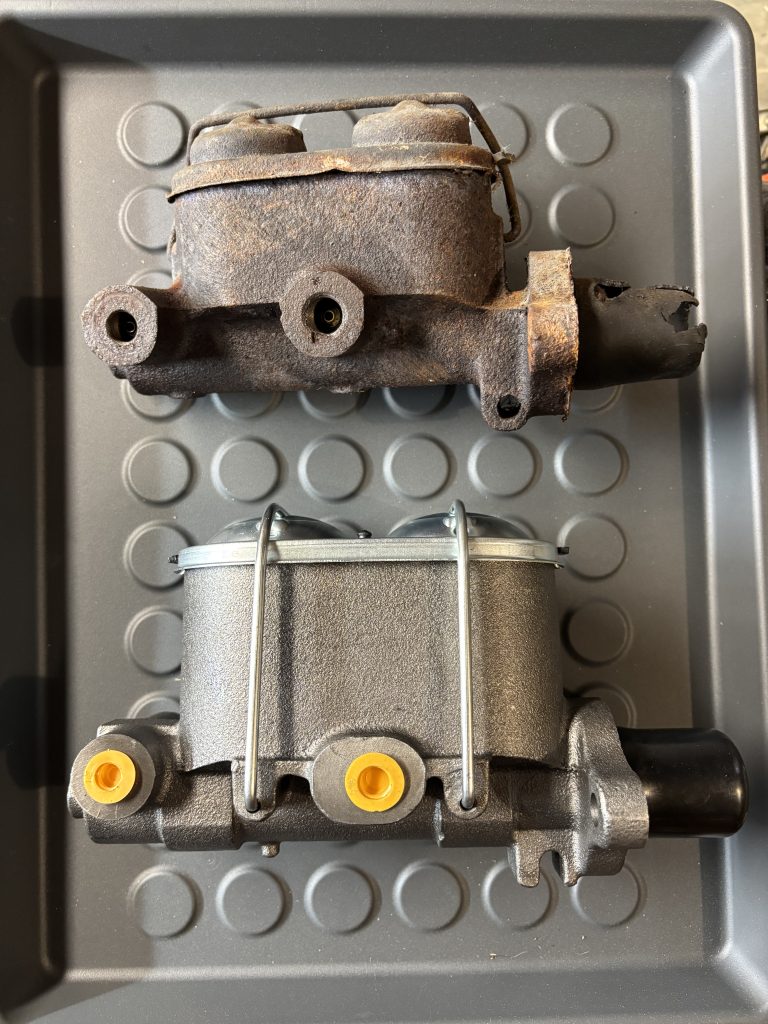

The master cylinder was the first problem, still the original drum/drum model. The casting number on the original master cylinder is 5452310. The difference between drum and disk circuits is the amount of residual line pressure that the master cylinder maintains in the circuit after the brake pedal is released. For drum brake circuits, the master cylinder keeps about 10psi so that the shoes are slightly extended, reducing the amount that the pedal has to travel before the brakes start working. Disc brake circuits need about 2psi, and if they get more, the pads will drag on the rotors. The master cylinder needed to be changed to one that had a disk brake circuit for the front brakes.

Getting the old master cylinder off was a challenge. The hard lines were rusty and not coming off easily, but they eventually gave in.

There was no front disk brake option in 1968, so the answer is a newer master. After some research, I settled on a NAPA M36280, which cross-references to a variety of disk/drum applications.

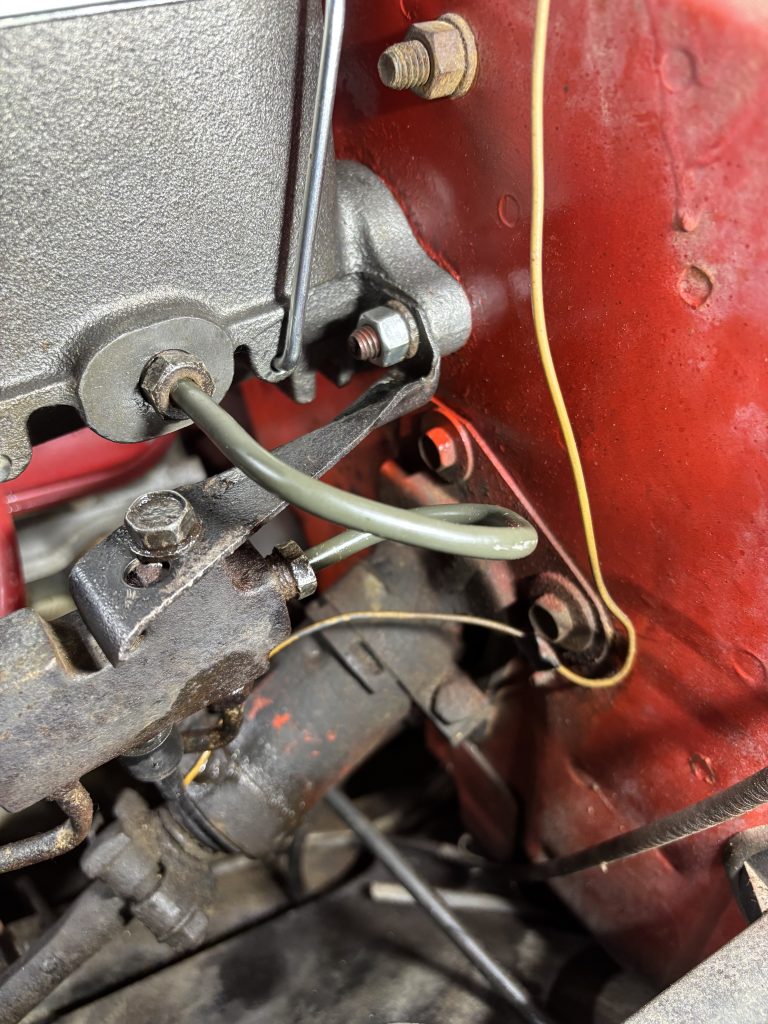

On installing the new master cylinder, the rear connection was not exactly in the same place, and bending the rear line cracked it and created a leak, so I made a replacement line.

I couldn’t bend it the same way that the original was, but I got something that worked.

After tightening everything up, no leaks finally.

I used a power bleeder to bleed the lines.

The fronts went well, the rears were a mess. One side had the bleeder broken off, and the other side had a sheetmetal screw wedged in the hole where the bleeder used to be. The rear brakes needed to be rebuilt.