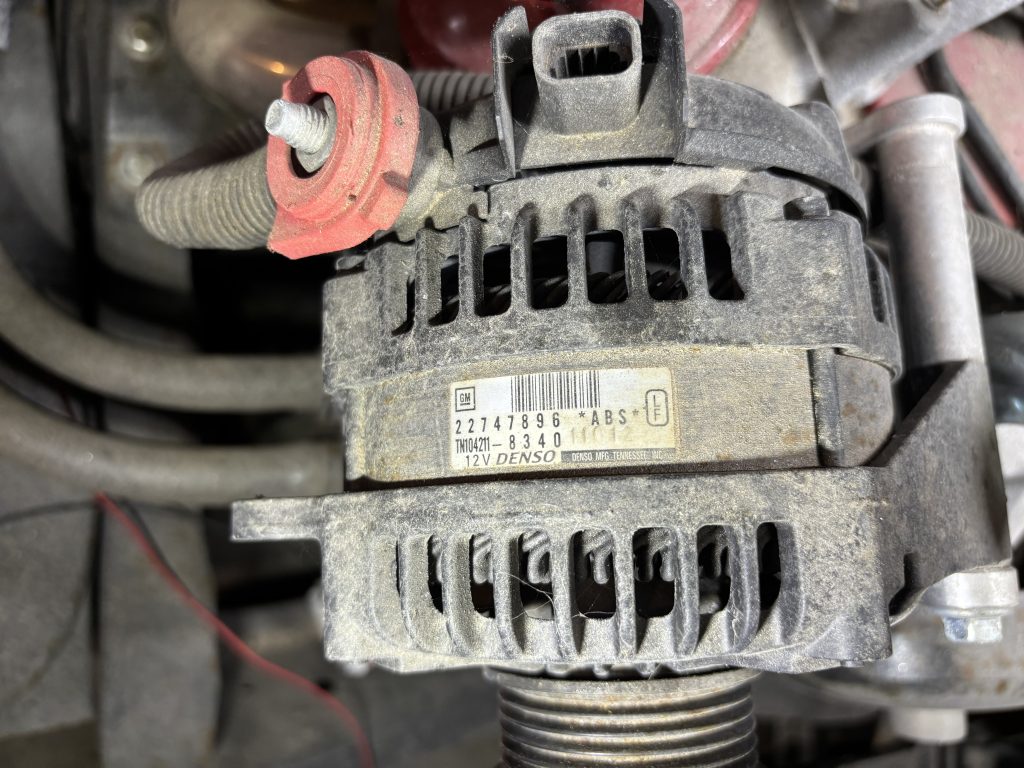

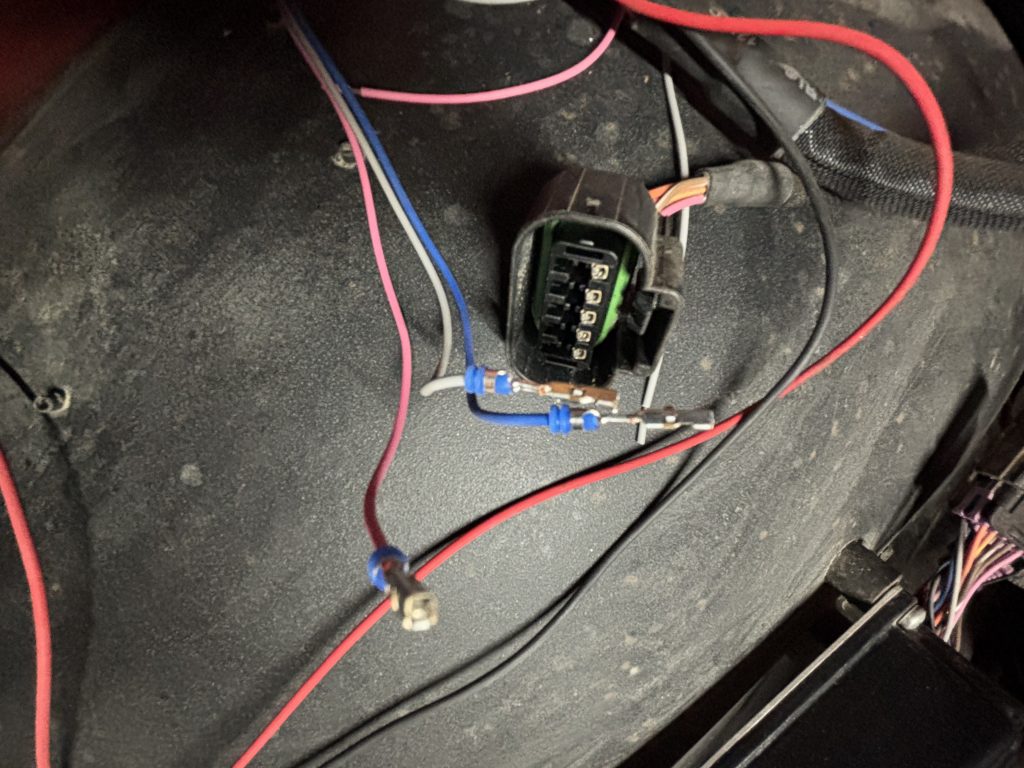

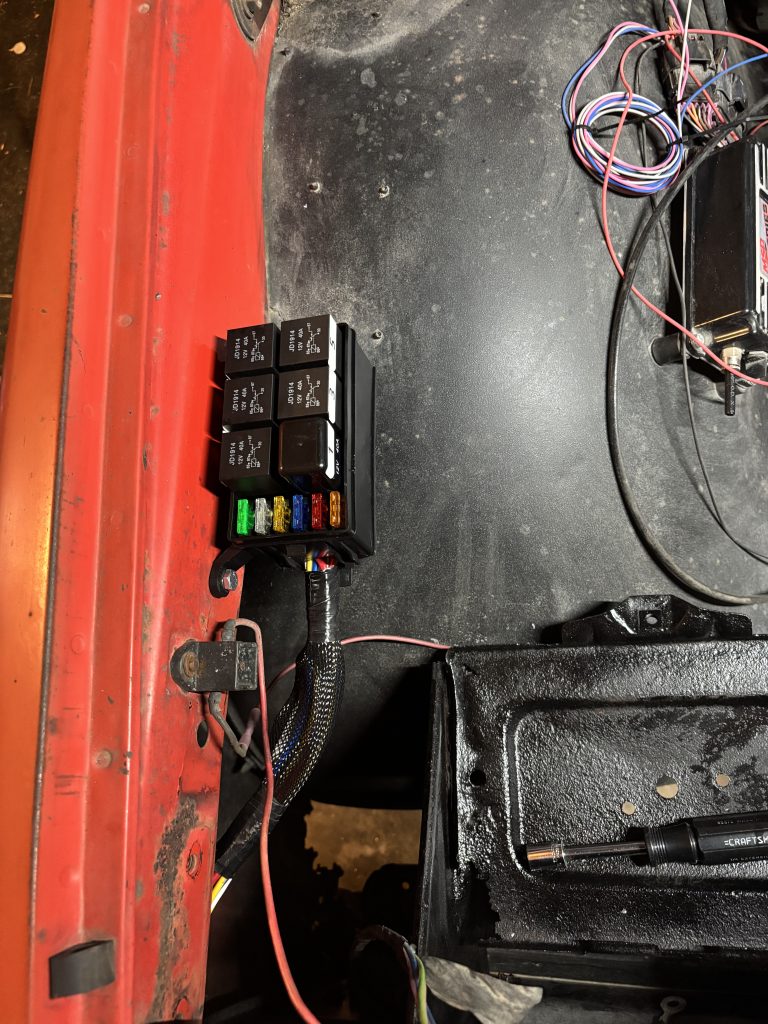

The alternator is mounted on the right side of the engine using a bracket made by ICT. When I wired the battery, I did some research on the alternator to see what I needed to wire up to get it working. This alternator had the big heavy cable from the battery, and also two smaller connections provided in a plug at the top. These are labeled “F” and “L” on the case. After doing some research, I found Dirty Dingo’s excellent writeup on alternators.

The good news is that the writeup explains everything you would want to know about alternators commonly found on LS engines. The bad news is that this two-wire interface depends on a computer managing it to set the output voltage. It defaults to 13.8 volts (limp-home mode) which will sorta work, but that’s lower than you want. It’s not an easy retrofit to a non-computer setup. I am going to try to get one of the other alternator models that are easier to retrofit. I’ll hook this up in the meantime, but eventually it will need to get replaced.