The truck came with a bunch of parts in the bed, including two electric fan setups. Both of these appear to have come from junkyards.

One is a dual-fan setup with straight blades. This one has a fair amount of damage to the plastic shroud. It will work, but it’s a little beat-up.

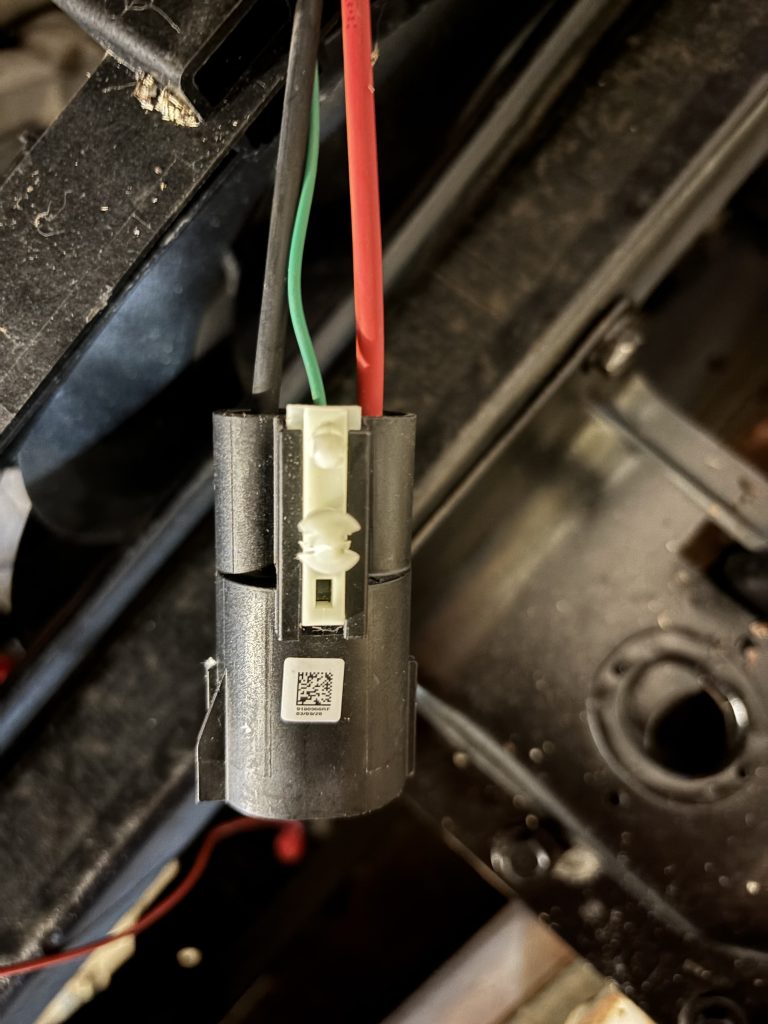

The other one is a single large fan that has a shroud that is 24″ x 26″, with a fan diameter of 21″. Looking up the numbers on the fan, this is a 2020-2024 Ford Explorer piece. The connector has 3 wires on it, two very big ones, and one smaller one. After some research, this 3rd wire is a PWM signal wire. The fan was originally controlled by the engine computer, and the width of the pulses on the signal line control how fast the fan runs.

I found a controller that I bought that is supposed to allow me to connect a temperature input to it, and the signal wire

will tell the fan the right thing to do.

The fan is fairly large, and is actually taller than the opening in the radiator support, but the frame is below the support, and that gives some extra room to work with.